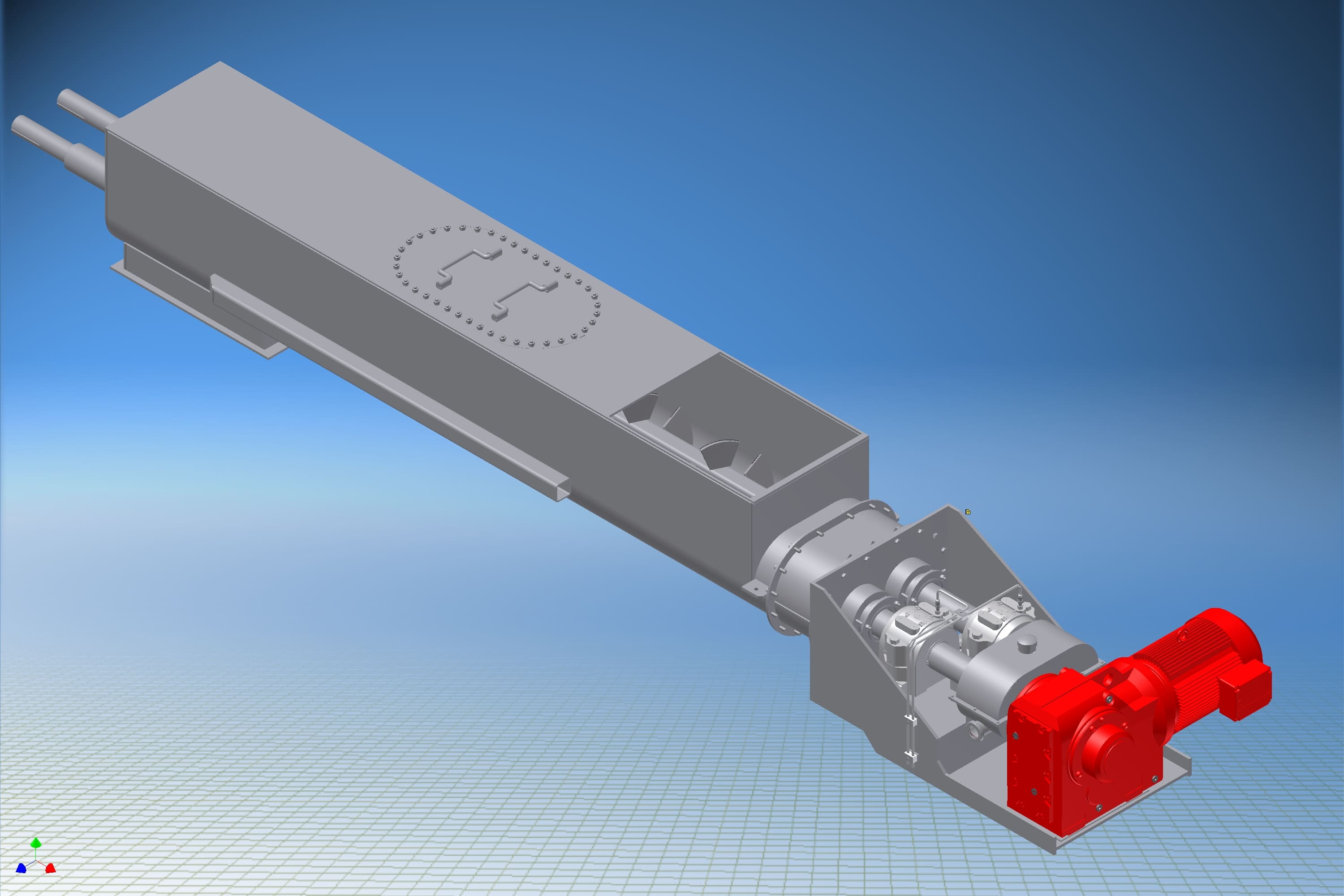

Engineering & Design for the Most Complex Projects

Our in-house engineers are here to help you build the helical product you need. From small and simple to large-scale and complex, we have experience in designing helical screws, piles, conveyors and more.

Bring us your exact specifications and requirements or let our logistics team take care of the details. Get in touch to speak with a qualified Helical Works Co. engineering specialist today and get started on your next project.

An Example of Advanced Engineering for Bucket Elevators

In a system as large and complex as a granary operation, every component matters. Components like bucket elevators operate 24/7, which means a single stop in motion means a stop in production and costly downtime.

When the Helical Works team provides engineering services, we’re not just looking at the cost of the component. We also have to consider how that component will stand up to extended use without failing. Wear and tear is the single biggest cause of downtime in industrial and commercial applications.

To minimize downtime for any clients we work with, our engineers spend time looking at the component in the context of the complex system, environment, and business it belongs to. Alignment, speed, motion, and outside factors such as temperature and moisture can all impact how a bucket elevator – or any helical product – performs over time. We take the time to provide assessments and concerns ahead of time to prevent delays in the manufacturing and installation process.

Speak With An Expert

Specifications for Custom Helical Product Engineering

- Torque capacity

- Flexibility

- Maintenance

- Resistance

- Size

- Materials