Understanding True Form Sectional Helices

For those of you who are highly technical this is the detail that matters in producing top quality auger flighting products.

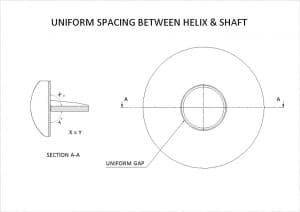

Accurate fit to shaft for efficient handling – The helix flight should click into position on the specified shaft in an efficient tight manner and without any secondary process such as grinding or cutting

Uniformity for weld procedure – Critical to “robotic welding processes” and very important to manual operations is the consistency of;

- Pitch angle – If pitch angle is not a uniform linear spiral, welding will require a variety of tracking adjustments to follow the non linear spiral

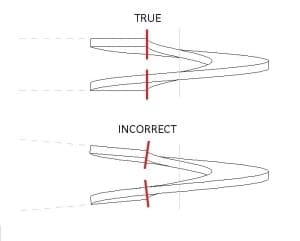

- Helix flange perpendicular to shaft – a typical incorrect helix usually causes a variety of weld angles around the helix. This will affect both the positional requirements of the weld, and consistency of both throat and root of welding between helix and shaft

- Helix internal edge parallel to shaft – the potential variability in the gap between the shaft and the edge of the inner helix edge. If not parallel, can result in a significant variation in the weld root and hence consistency and quality of weld.

- Therefore – A true pitch helix shall have;

- Flange perpendicular to shaft and;

- Uniform pitch angle